In a world increasingly conscious of climate change, animal welfare, and environmental degradation, the fashion industry has begun seeking innovative, ethical, and sustainable materials. One such revolutionary material is Piñatex, a vegan leather alternative made from the fiber of pineapple leaves. A product of innovation and eco-conscious ingenuity, Piñatex has emerged as a powerful contender in the sustainable fashion world, blending ethics with aesthetics.

From high-end designer handbags to everyday sneakers, Piñatex is redefining the potential of plant-based textiles. In this blog post, we will explore everything about pineapple leather—how it’s made, where it’s produced, its growing demand, applications in fashion, comfort level, cost factors, and more.

What is Piñatex?

Piñatex is a natural leather alternative made from the cellulose fibers of pineapple leaves. It was developed by Dr. Carmen Hijosa, a Spanish designer and entrepreneur, who, after witnessing the environmental and ethical issues in traditional leather tanning, sought to create a better alternative. Piñatex is manufactured by the company Ananas Anam, founded by Dr. Hijosa in the UK.

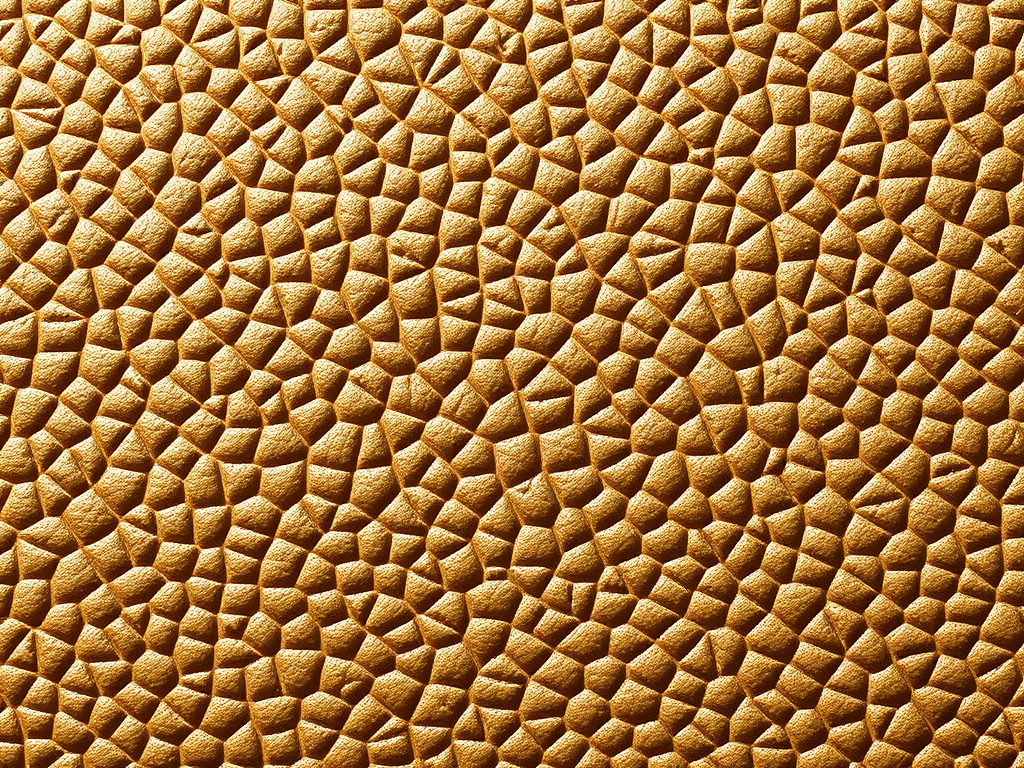

Piñatex has the texture of felted leather, is breathable, flexible, and versatile enough for use in fashion, upholstery, accessories, and footwear.

How is Piñatex Made?

The process of creating Piñatex is both innovative and sustainable, relying on agricultural waste and requiring no additional land, water, or pesticides.

1. Collection of Pineapple Leaves

- After pineapples are harvested, the leaves—typically discarded or burned—are collected.

- These leaves come primarily from pineapple plantations in the Philippines.

2. Fiber Extraction (Decortication)

- The leaves undergo a process called decortication, where fibers are extracted using semi-automated machines near the farms.

3. Degumming and Drying

- Extracted fibers are washed and dried naturally in the sun.

- They are then degummed to remove lignin and other plant residues, resulting in a soft, fluffy material known as PALF (Pineapple Leaf Fiber).

4. Production of Non-Woven Mesh

- The fibers are processed into a non-woven mesh, similar to felt, using mechanical bonding techniques.

5. Finishing with Bio-Based Coating

- This mesh is then coated with a water-based PU (polyurethane) resin or bio-based PU to give it leather-like durability and sheen.

- In newer formulations, more plant-based resins are used to reduce plastic content.

6. Final Rolls of Piñatex

- The result is a durable, soft, and pliable material that mimics animal leather and is ready for cutting, stitching, and design applications.

Where is Piñatex Made?

The production of Piñatex spans multiple countries:

- Philippines: The main source of pineapple leaves.

- Spain and the UK: The non-woven mesh and finishing processes are primarily carried out here.

- Other partner countries: Thailand, Indonesia, and some parts of South America are beginning to contribute to raw material supply and processing.

Ananas Anam’s supply chain is built on local partnerships with farming communities, thereby supporting rural economies and reducing waste.

Why is Piñatex in High Demand?

Several factors contribute to the rising demand for Piñatex in the fashion and lifestyle industries:

1. Eco-Friendly Innovation

- Piñatex uses agricultural waste, reducing the environmental burden of both leather and synthetic leather production.

- It doesn’t require additional water, fertilizers, or land.

2. Animal-Free and Vegan

- In an age of cruelty-free fashion, Piñatex provides a stylish alternative without harming animals.

3. Fashion-Forward Aesthetic

- The fabric is visually appealing, with a natural texture and versatile finish that can be dyed, embossed, or polished.

4. Circular Economy Contribution

- Since it’s derived from waste, Piñatex encourages resource circularity and supports zero-waste manufacturing models.

Why is Piñatex Costly?

While Piñatex is sustainable, it’s still a premium-priced product. Here’s why:

1. Labor-Intensive Process

- The fiber extraction and degumming processes are still partially manual and require skilled labor.

2. Limited Supply Chain

- Compared to leather or synthetic alternatives, Piñatex is not yet mass-produced on a global scale, which keeps costs higher.

3. R&D and Innovation

- As a relatively new material, substantial investments go into research, testing, and technology development to improve quality and reduce environmental impact.

4. Eco-Coatings

- The bio-based or water-based coatings used in Piñatex are more expensive than petrochemical-based alternatives.

5. Ethical Supply Chain

- Piñatex production supports fair wages and local farming communities, reflecting ethical pricing models.

How Comfortable is Piñatex?

While Piñatex is not as breathable or soft as cotton or bamboo fabric, it offers unique comfort properties within its category (leather alternatives).

Comfort Highlights:

- Lightweight: Easier to carry than traditional leather, especially for shoes and bags.

- Flexible: Moldable and softens over time with wear.

- Hypoallergenic: Plant-based, with no animal dander or toxins.

- Water-resistant: Can withstand light moisture, though not fully waterproof.

However, Piñatex is primarily used in outerwear and accessories, rather than as a base layer fabric. So its “comfort” is more structural than sensory.

What Can Be Made from Piñatex?

Piñatex is a highly versatile material and can be used across multiple design sectors:

1. Fashion

- Footwear: Sneakers, boots, sandals

- Jackets: Moto-style jackets with texture and durability

- Bags: Tote bags, backpacks, and clutches

- Wallets & Belts: Durable and stylish vegan alternatives

2. Accessories

- Watches straps

- Phone cases

- Eyewear holders

- Laptop sleeves

3. Home Décor

- Upholstery

- Cushion covers

- Wall panels

4. Automotive

- In prototypes and luxury concept cars for car seat covers and interiors

5. Art & Innovation

- Piñatex is even being explored in architecture, furniture design, and wearable technology.

In Which Season is Piñatex More Comfortable?

Piñatex is more season-neutral, especially as it’s mostly used for accessories and outer layers rather than breathable innerwear. But here are some seasonal insights:

Summer:

- Ideal for bags, sandals, and lightweight accessories.

- Doesn’t heat up like faux leather or PVC in direct sun.

Monsoon:

- Slightly water-resistant, so Piñatex items like shoes or bags can resist splashes.

- However, not fully waterproof—should be kept dry.

Winter:

- Provides a leather-like feel without stiffness, making it a good choice for stylish jackets and boots.

Environmental Impact of Piñatex

Piñatex is not only a trend—it is a solution to textile and agricultural waste.

Sustainability Factors:

- Made from waste leaves, reducing agricultural burning and CO₂ emissions.

- Requires no additional water, land, or pesticides.

- Partially biodegradable (though the coating may not be unless bio-based).

- Low energy use in production.

- Encourages social sustainability by empowering farming communities.

Ananas Anam claims that every one ton of Piñatex prevents around 16 metric tons of CO₂ emissions, primarily by avoiding leaf burning.

Piñatex vs Leather vs Faux Leather

| Property | Piñatex | Animal Leather | Faux Leather (PVC/PU) |

|---|---|---|---|

| Source | Pineapple leaves | Animal hide | Petroleum-based plastics |

| Sustainability | Very High | Low | Very Low |

| Biodegradability | Partial | Biodegradable | Non-biodegradable |

| Comfort | Moderate | High | Low to Moderate |

| Weight | Light | Heavy | Light |

| Water Resistance | Moderate | High (with treatment) | High |

| Cost | Medium-High | High | Low |

| Ethical Production | Yes (Vegan) | No (Animal-based) | Yes, but unsustainable |

Certifications and Ethical Assurance

While Piñatex is not always certified organic (since it’s made from waste), Ananas Anam ensures:

- Vegan certification by PETA

- Partnerships with B Corp and Cradle to Cradle standards

- Supply chain transparency and social impact reports

Brands using Piñatex often adhere to slow fashion principles, ethical manufacturing, and fair trade sourcing.

Future of Piñatex in Fashion

As innovations continue, Piñatex is evolving:

- Piñatex Performance: More water-resistant version for sportswear and accessories.

- Piñatex Mineral & Piñatex Metallic: Metallic finishes for glam and luxury products.

- Biodegradable coatings in development to replace PU.

The potential for scaling production, reducing costs, and increasing biodegradability makes Piñatex a promising material for a circular economy.

Piñatex (pineapple leather) is more than just a trend—it’s a symbol of innovation, ethics, and environmental responsibility. For consumers looking to reduce their fashion footprint without compromising on style or function, Piñatex offers a compelling alternative.

From sustainable fashion lovers to established luxury brands, the shift towards plant-based materials like Piñatex is a crucial step in transforming the fashion landscape for the better.

Leave a comment